Performance characteristics:

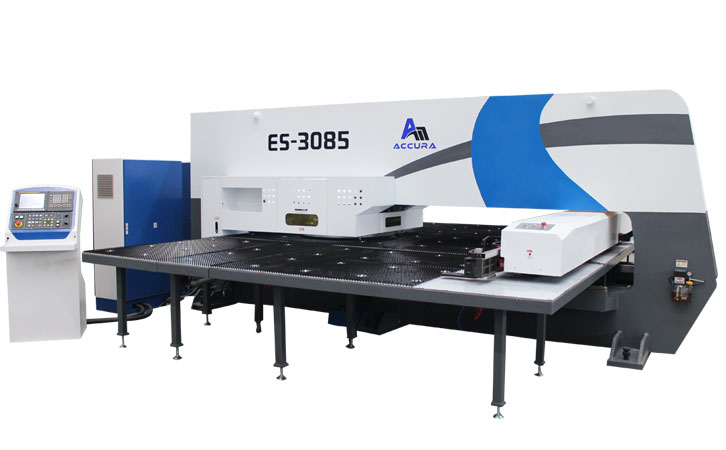

1. The fully electric servo CNC turret punch machine uses a high torque servo motor as the power source of the punch, with superior performance of high precision, high efficiency, and low noise. It can achieve processes such as punching, forming, rolling, and marking.

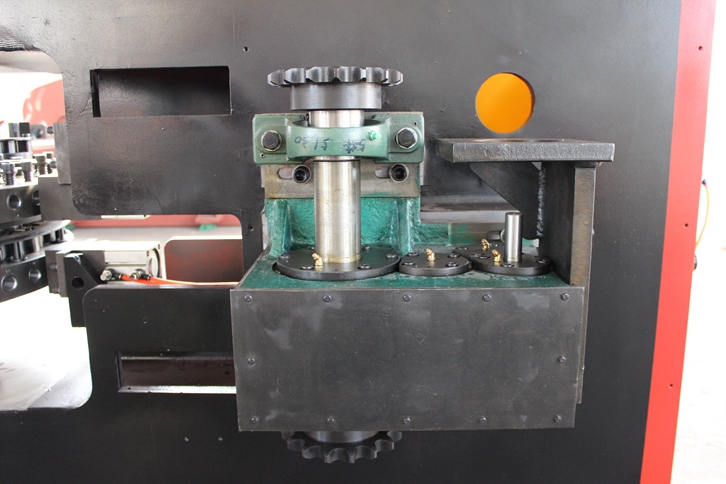

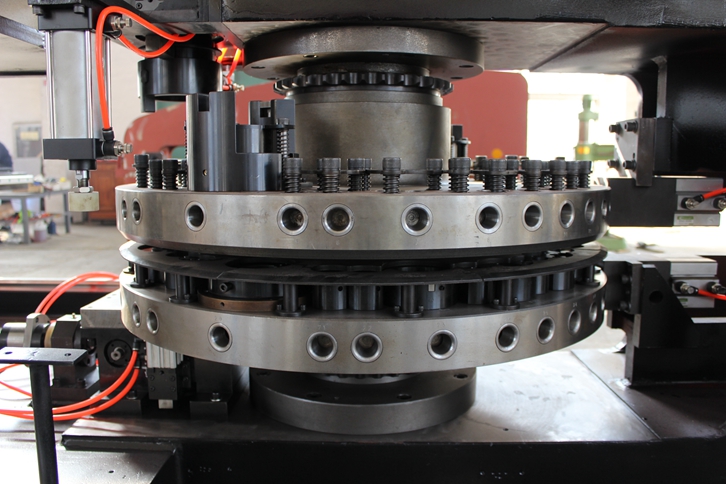

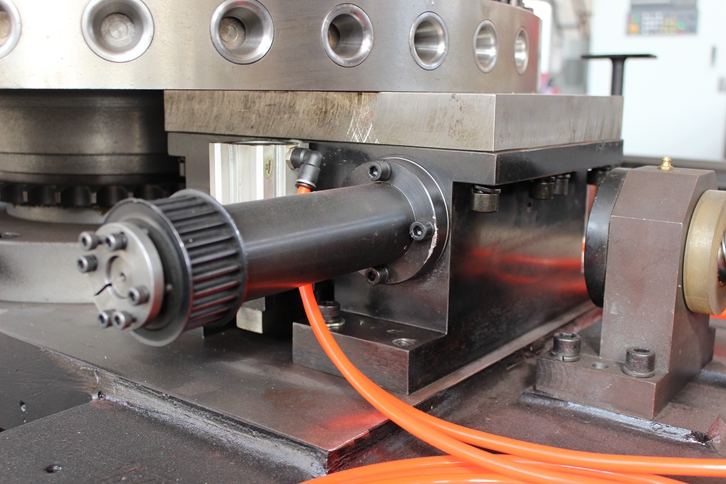

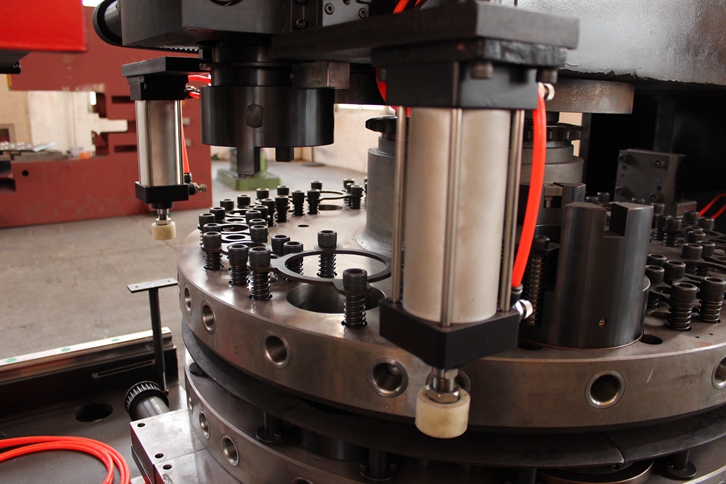

2. The turret transmission adopts a three-level gear transmission gearbox to ensure the accuracy and stability of the turret during high-speed rotation.

3. Equipped with the company''s newly upgraded CNC punching machine dedicated system, easy to operate and user-friendly interface; Intelligent clamp avoidance, with repositioning function, can achieve no dead zone processing;

4. Equipped with RS232 standard interface to achieve data transmission on the fifth axis, and equipped with a network card for convenient connection and communication with other computers, local area networks, and the World Wide Web;

Equipped with a 120G solid-state hard drive, it can achieve high capacity and high-speed storage of files;

6. Industrial grade brand computer control, earthquake resistant, anti-interference,

7. Specialized CNC punching programming software that enables conversion between graphics and code, with functions such as automatic addition of stamping and automatic nesting;

8. Intelligent low noise and energy-saving stamping, the main servo motor only operates during stamping, greatly saving energy; Small stamping stroke and low noise.

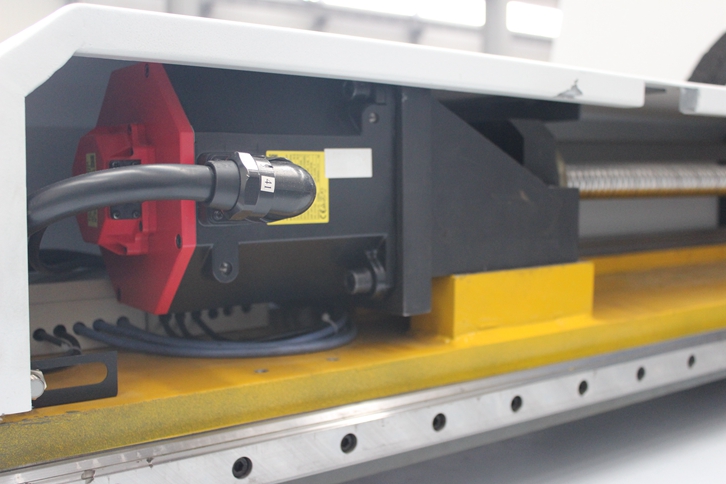

9. Taiwan imports precision large lead ball screws, which better ensure high machining accuracy and work efficiency;

10. Taiwan imported precision linear guide rails ensure higher precision and longer service life;

11. Brand coupling ensures long-lasting durability and high correction coefficient;

12. Japanese brand servo drives and motors;

13. Simple graphics can be set up for mold library selection in CAD drawings, and preview patterns and generate codes in CAD files;

14. The board can automatically repeat positioning after the program is executed, with precise positioning, which can achieve large-scale board processing;

During batch processing, one click operation can be achieved, making it convenient and fast;

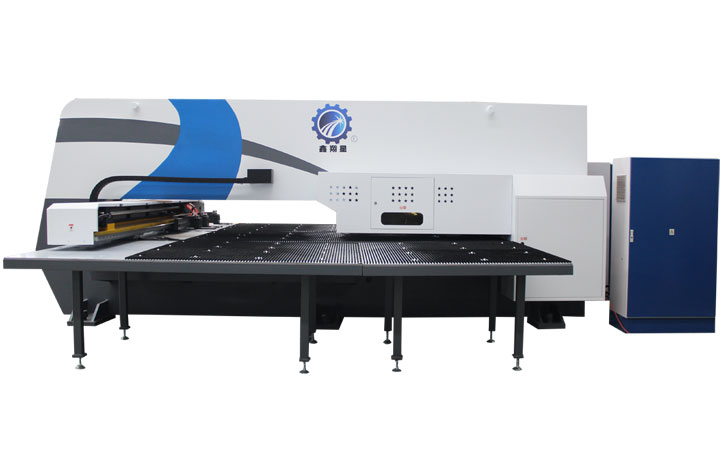

16. The punching machine body adopts a steel plate welding structure, with good rigidity, small deformation, large closing height, long mold guide, convenient and reliable use, low noise, and long service life;

17. Mix the universal ball and brush on the workbench to be suitable for punching different plate thicknesses

18. The motor cables are protected by protective wire sleeves, which are oil resistant, waterproof, and pollution resistant;

19. The main electrical components are placed in the electrical box to prevent wire leakage, which is both safe and convenient for maintenance and protection.

20. Equipped with an automatic centralized lubrication pump, the lubricating oil is directly fed into each lubrication point, reducing labor intensity of workers, reducing friction of each motion pair, and improving service life;

21. There is an alarm display for multiple mechanical and electrical faults such as overtravel.

22. Equipped with mold compensation and reverse clearance compensation functions.

23. With breakpoint processing function.